Pistons Replacement Guide: 2 Key Steps for Efficient AC Performance

In the sweltering heat of summer, air conditioning is a modern-day blessing that keeps our homes and workplaces comfortable. However, like all mechanical systems, air conditioners require regular maintenance to function at their best. One often overlooked aspect of AC maintenance is piston replacement. In this comprehensive blog, we’ll delve deep into the world of pistons in air conditioning systems and explore why their replacement is vital for ensuring efficient AC performance.

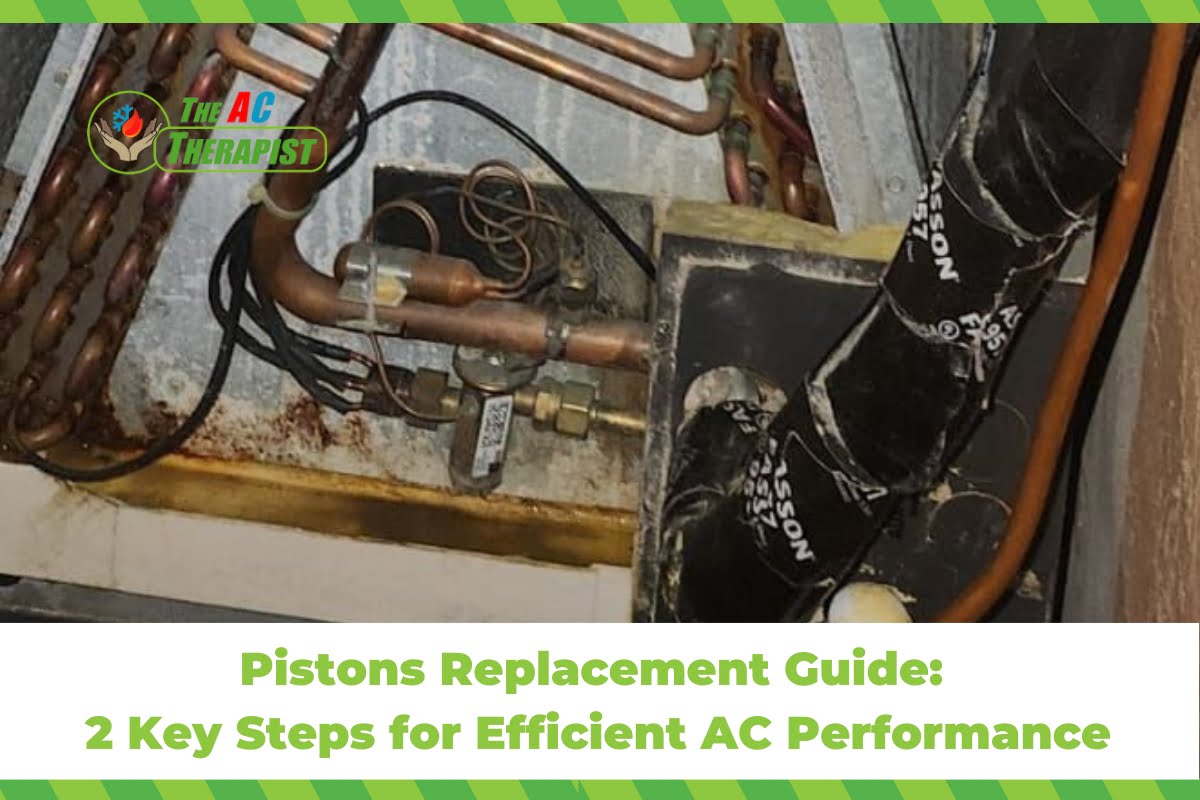

The Heart of the Cooling System – AC Pistons

Air conditioning systems are intricate marvels of engineering, and at the heart of these systems are AC pistons, often regarded as the unsung heroes of cooling. In this chapter, we’ll explore the vital role that pistons play in the refrigeration cycle and how they form the core of the cooling process.

The Piston’s Role in Refrigeration

Imagine the refrigerant in your air conditioner as a vital fluid that carries heat away from your indoor space. The piston’s role is to regulate the flow of this refrigerant, ensuring it moves through the system efficiently.

- Compression: The journey begins with the compressor, where the refrigerant is initially compressed. This compression raises its temperature and pressure, transforming it into a high-energy gas ready for heat exchange.

- Piston’s Entry: The compressed refrigerant then enters the piston chamber. The piston itself is a movable component, often made of durable materials like brass or steel. Its design allows it to fit snugly within the cylinder, creating a seal.

- Regulating Flow: The piston’s movement is synchronized with the cooling demand. When more cooling is required, the piston allows a higher flow of refrigerant, and when less cooling is needed, it restricts the flow. This precise regulation is what maintains consistent indoor temperatures.

Temperature and Pressure Control

One of the piston’s essential functions is to control the temperature and pressure of the refrigerant as it moves through the system. This control is crucial for efficient cooling. Here’s how it works:

- Expansion Valve Effect: As the high-pressure refrigerant enters the piston chamber, the piston’s position determines how much refrigerant can flow out. When the piston is fully open, more refrigerant is released, leading to lower pressure and temperature. Conversely, when the piston partially closes, it restricts the flow, resulting in higher pressure and temperature.

- Heat Absorption: When the refrigerant flows through the evaporator coil inside your AC unit, it encounters warm indoor air. The low-pressure, low-temperature refrigerant absorbs heat from the air, cooling it in the process.

- Repeat Cycle: The now-warmed refrigerant returns to the compressor, where the cycle begins anew. It’s the piston’s precision that ensures this cycle repeats continuously, maintaining a comfortable indoor environment.

Piston Design and Efficiency

Efficiency is paramount in any air conditioning system. The design of the piston is critical to achieving optimal performance. Engineers carefully consider factors like piston size, material, and the tightness of its seal to maximize efficiency.

- Size Matters: The size of the piston determines the volume of refrigerant that can flow through it. A properly sized piston ensures the right amount of refrigerant reaches the evaporator coil, preventing overcooling or undercooling.

- Material Selection: Pistons are typically made from durable materials that can withstand the demands of the cooling process. Brass and steel are common choices due to their strength and resistance to corrosion.

- Sealing Perfection: The piston must create a tight seal within the cylinder to prevent refrigerant leaks. Even small leaks can compromise efficiency and cooling performance.

In conclusion, AC pistons are the heart of the cooling system, regulating the flow, temperature, and pressure of refrigerant to ensure your air conditioner works efficiently and effectively. Their precise operation allows you to enjoy the cool comfort of your indoor space even on the hottest days of summer. Understanding their role underscores the importance of regular maintenance and, when necessary, piston replacement to keep your AC system in top shape.

Types of Pistons

Not all pistons in air conditioners are created equal. There are different types of pistons, each with its own set of characteristics and applications. In this chapter, we’ll explore the various types of pistons commonly found in air conditioning systems.

1. Fixed Orifice Pistons

Fixed orifice pistons, also known as standard pistons, are the most common type found in residential air conditioning systems. They have a fixed-size orifice, which means the opening through which refrigerant flows cannot be adjusted. These pistons are carefully selected to match the specific design and cooling capacity of the AC unit.

- Simplicity: Fixed orifice pistons are straightforward in design and operation, making them reliable components in many AC systems.

- Compatibility: They are typically designed to work with a particular range of air conditioning systems, ensuring compatibility and efficient operation.

- Lower Cost: Fixed orifice pistons are often more cost-effective than other types, which can make them an attractive option for budget-conscious consumers.

2. Thermostatic Expansion Valve (TXV) Pistons

While not technically pistons in the traditional sense, TXVs are often referred to as piston-type expansion valves. They play a crucial role in regulating refrigerant flow in more complex and high-efficiency air conditioning systems. Here’s how they differ:

- Adjustable Flow: Unlike fixed orifice pistons, TXVs allow for adjustable refrigerant flow. This adaptability makes them ideal for systems with varying cooling demands.

- Precision Control: TXVs are known for their ability to precisely control superheat, which is the temperature of the refrigerant as it exits the evaporator coil. This ensures efficient cooling and prevents issues like refrigerant flooding.

- High Efficiency: TXVs are commonly used in high-efficiency HVAC systems because of their ability to optimize refrigerant flow based on real-time conditions.

3. Bi-Flow Pistons

Bi-flow pistons are a specialized type designed for heat pump systems. Heat pumps have the unique ability to provide both cooling and heating by reversing the refrigeration cycle. Bi-flow pistons are essential in this process as they control refrigerant flow in both directions.

- Reversing the Cycle: In heating mode, the bi-flow piston allows the refrigerant to flow in the opposite direction, ensuring efficient heating performance.

- Balanced Operation: Bi-flow pistons help maintain balanced refrigerant flow in both cooling and heating modes, optimizing the system’s overall efficiency.

4. Non-adjustable and Adjustable Pistons

Within the fixed orifice category, there are non-adjustable and adjustable pistons. Non-adjustable pistons have a set orifice size and cannot be changed. Adjustable pistons, on the other hand, can be fine-tuned to match the specific requirements of the AC system.

- Customization: Adjustable pistons offer the advantage of customization, allowing HVAC technicians to optimize the refrigerant flow for improved efficiency.

- Precision: They can be precisely adjusted to achieve the desired superheat, which is essential for efficient cooling.

How Pistons Control Refrigerant Flow

Pistons play a pivotal role in controlling the flow of refrigerant within an air conditioning system. To appreciate their significance, it’s essential to understand how pistons exert control over refrigerant flow, influencing the entire cooling process. In this chapter, we’ll explore the mechanics behind piston operation and how they contribute to efficient air conditioning.

1. The Refrigeration Cycle Overview

Before delving into piston operation, let’s briefly recap the fundamental stages of the refrigeration cycle in an air conditioner:

- Compression: The cycle begins in the compressor, where low-pressure, low-temperature refrigerant is compressed into a high-pressure, high-temperature gas.

- Condensation: The high-pressure gas flows to the condenser coil outside the AC unit. Here, it releases heat and condenses into a high-pressure liquid.

- Expansion: The high-pressure liquid moves into the expansion device, which can be a piston or a thermostatic expansion valve (TXV). This is where the magic happens.

- Evaporation: The refrigerant, now in a low-pressure, low-temperature state, enters the evaporator coil inside the building. It absorbs heat from the indoor air, cooling it in the process.

2. The Role of the Piston

Now, let’s focus on the expansion phase and how pistons control refrigerant flow:

- Entry into the Piston Chamber: The high-pressure liquid refrigerant enters the piston chamber from the condenser. The piston is a movable component within this chamber.

- Piston Movement: The piston’s movement is controlled based on the cooling demand. When more cooling is needed, the piston allows a greater flow of refrigerant. When less cooling is required, it restricts the flow.

- Adjusting Pressure and Temperature: As the piston moves, it adjusts the size of the opening through which the refrigerant can pass. When fully open, it allows more refrigerant to flow, which results in lower pressure and temperature. Conversely, when partially closed, it restricts the flow, leading to higher pressure and temperature.

- Maintaining the Cycle: The refrigerant, now in a low-pressure, low-temperature state, exits the piston chamber and enters the evaporator coil, where it can absorb heat from the indoor air. This completes the cycle, as the warm air is cooled and circulated back into the living space.

3. Precision and Efficiency

The key to efficient air conditioning lies in the precision of refrigerant flow control by the piston:

- Consistent Cooling: The piston’s ability to precisely control refrigerant flow ensures that the cooling process remains consistent. This means that your indoor environment maintains a stable, comfortable temperature.

- Preventing Overcooling or Undercooling: By adjusting refrigerant flow based on demand, the piston prevents overcooling or undercooling, optimizing energy use.

- Balancing the System: Piston operation helps balance the air conditioning system, ensuring that the evaporator coil receives just the right amount of refrigerant for efficient heat exchange.

Signs Your AC Piston Needs Replacement

Recognizing the signs that your AC piston requires replacement is crucial for maintaining your air conditioner’s efficiency and preventing potential issues. In this chapter, we’ll explore common indicators that suggest it might be time to consider replacing the AC piston.

1. Reduced Cooling Efficiency

One of the earliest signs that your AC piston might need replacement is a noticeable decrease in cooling efficiency. If your air conditioner is struggling to maintain the desired temperature or takes longer to cool your space, it could be due to a malfunctioning piston.

- Cause: Over time, pistons can wear out or develop leaks, leading to inefficient regulation of refrigerant flow. This results in reduced cooling capacity.

2. Uneven Temperature Distribution

Uneven cooling throughout your space is another telltale sign of piston problems. If certain rooms or areas in your home consistently feel warmer than others, it may indicate that the piston isn’t regulating refrigerant flow properly.

- Cause: Malfunctioning pistons can lead to an imbalance in refrigerant distribution, causing some areas to receive more cooling than others.

3. Frequent Cycling On and Off

If your AC unit is cycling on and off more frequently than usual, it can be a sign of piston issues. This constant cycling not only strains the system but also results in higher energy bills.

- Cause: A faulty piston can cause the system to overcompensate for temperature discrepancies, leading to more frequent cycling as it attempts to maintain the desired temperature.

4. Increased Energy Bills

Keep an eye on your energy bills. If you notice a significant and unexplained increase in your cooling costs, it could be attributed to a piston that’s not operating efficiently.

- Cause: An inefficient piston forces your AC system to work harder to achieve the desired cooling, leading to higher energy consumption.

5. Ice Formation on the Evaporator Coil

Ice formation on the evaporator coil is a clear sign of refrigerant flow issues. If you see ice accumulating on the indoor unit’s coil, it may indicate that the piston is not regulating the flow properly.

- Cause: Inadequate refrigerant flow, often caused by a malfunctioning piston, can lead to temperature drops below freezing within the evaporator coil, resulting in ice formation.

6. Strange Sounds

Unusual noises coming from your AC unit, such as hissing, gurgling, or clicking sounds, can be indicative of piston problems. These noises may suggest refrigerant flow disruptions within the system.

- Cause: Malfunctioning pistons can lead to turbulence and irregular refrigerant flow, creating audible disturbances.

7. Refrigerant Leaks

If you observe refrigerant leaks around your AC unit or notice a drop in cooling performance accompanied by a hissing sound, it’s critical to address the issue promptly. Leaking refrigerant can be a sign of a piston that needs replacement.

- Cause: Worn-out pistons or damaged seals can result in refrigerant leaks, compromising the system’s cooling capacity.

8. Age of the AC Unit

Finally, consider the age of your air conditioning unit. If your AC system is approaching or has exceeded its expected lifespan, it’s wise to proactively replace the piston, even if you haven’t observed specific signs of malfunction. As components age, they are more prone to wear and tear.

Piston Maintenance and Troubleshooting

Regular maintenance is essential to ensure the smooth operation of the piston in your air conditioner. Additionally, knowing how to troubleshoot common piston-related issues can save you from costly repairs and discomfort. In this chapter, we’ll delve into piston maintenance and troubleshooting techniques.

1. Regular Maintenance

Routine maintenance can significantly extend the life of your AC piston and the overall efficiency of your cooling system. Here’s how to maintain your piston effectively:

- Annual Inspections: Schedule an annual HVAC inspection by a qualified technician. They will check for any signs of piston wear, leaks, or other issues.

- Filter Replacement: Ensure your air filters are clean and replaced regularly. Clogged filters can strain the AC system and affect piston performance.

- Cleaning: Keep the evaporator and condenser coils clean. Dirty coils can hinder heat exchange and, in turn, affect piston operation.

- Lubrication: If your piston is part of a larger assembly that requires lubrication, follow the manufacturer’s recommendations for lubricant type and schedule.

- Tighten Connections: Check and tighten any loose connections around the piston or other components. Loose fittings can lead to refrigerant leaks.

2. Troubleshooting Piston Issues

Despite regular maintenance, piston-related problems can still occur. Here’s how to troubleshoot and address common piston issues:

- Insufficient Cooling: If you notice that your air conditioner is not cooling adequately, check for any ice formation on the evaporator coil. If ice is present, it may indicate a piston problem or low refrigerant levels. In this case, it’s best to contact a professional HVAC technician to diagnose the issue accurately.

- Refrigerant Leaks: If you suspect a refrigerant leak, you may notice a hissing sound, reduced cooling performance, or ice on the evaporator coil. Refrigerant leaks are a serious concern and should be addressed promptly by a qualified technician. Do not attempt to repair refrigerant leaks yourself.

- Uneven Cooling: If certain areas of your space are consistently warmer than others, it could be due to an imbalance in refrigerant flow caused by a piston issue. A technician can adjust or replace the piston to resolve this problem.

- Frequent Cycling: If your AC unit is cycling on and off frequently, it might be due to a malfunctioning piston. This can lead to increased wear and tear on the system. A professional technician can diagnose and address this issue.

- Strange Noises: Unusual sounds, such as hissing or gurgling, can indicate refrigerant flow issues related to the piston. If you hear these noises, it’s best to have a technician inspect and resolve the problem.

- Refrigerant Pressure Problems: If your AC system is not maintaining the appropriate refrigerant pressures, it can affect piston performance. A qualified technician can diagnose and adjust the refrigerant charge as needed.

Seamless Comfort: Trust The AC Therapist for Your Piston Replacement Needs

In wrapping up this comprehensive exploration of AC piston replacement, we’ve delved into the crucial role these components play in your air conditioner’s performance. Recognizing the signs of piston wear and inefficiency is the first step toward ensuring optimal cooling and energy efficiency in your home or business.

When the time comes for piston replacement, it’s not just about restoring your AC’s performance; it’s about securing your comfort and peace of mind. That’s where professionals like The AC Therapist shine. With their expertise, they not only diagnose piston-related issues accurately but also ensure that the replacement process is carried out seamlessly, guaranteeing your HVAC system operates at peak efficiency.

The AC Therapist, a trusted local residential and light commercial HVAC contractor in the Tampa Bay area, specializes in air conditioning services, including piston replacement. Their commitment to excellence and customer satisfaction means you can trust them with your cooling needs.

So, whether you’ve noticed reduced cooling efficiency, uneven temperature distribution, or any other signs of piston wear, don’t hesitate to reach out to The AC Therapist. With their Therapy Maintenance Plans and skilled technicians, they offer not just repairs, but a pathway to consistent, efficient, and comfortable indoor environments.

In the world of HVAC, where comfort meets efficiency, The AC Therapist is your reliable partner. Schedule your piston replacement with confidence and ensure your AC system continues to deliver the cooling comfort you deserve.