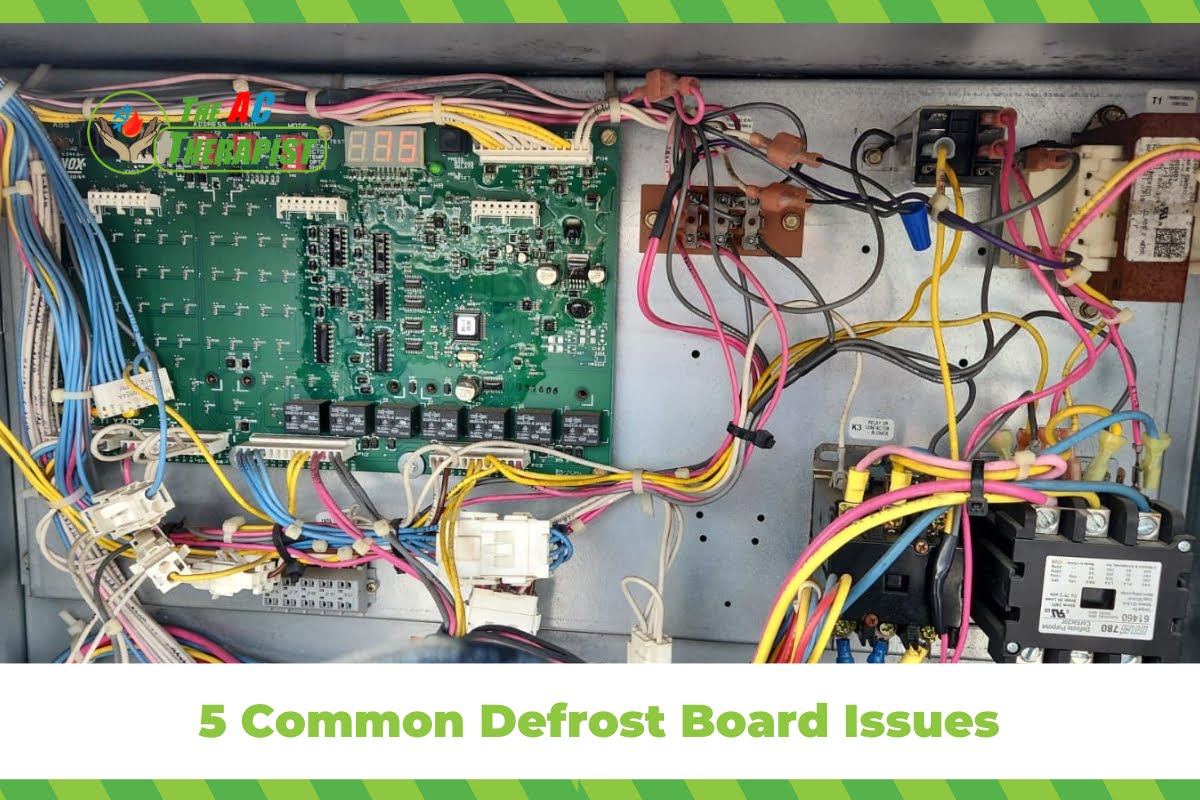

5 Common Defrost Board Issues

In the realm of HVAC systems, particularly those involving heat pumps, the defrost board is a critical component that ensures efficient operation during colder months. This comprehensive guide aims to provide homeowners and HVAC professionals with an in-depth understanding of common defrost board issues, offering detailed troubleshooting techniques and insights into maintaining these systems for optimal performance.

Introduction to Defrost Boards

In the world of heating, ventilation, and air conditioning (HVAC) systems, particularly those involving heat pumps, the defrost board plays a pivotal role in ensuring efficient operation during the colder months. Understanding the function and importance of the defrost board is crucial for both homeowners and HVAC professionals, as it helps in maintaining the system’s efficiency and longevity.

What is a Defrost Board?

A defrost board, also known as a defrost control board, is an electronic component found in most modern heat pump systems. Its primary function is to control the defrost cycle of the heat pump. The defrost cycle is a critical process that prevents the accumulation of frost or ice on the outdoor unit’s evaporator coils.

During colder weather, the outdoor unit of a heat pump can accumulate frost, which can impede the heat transfer process and reduce the efficiency of the system. If left unchecked, this frost build-up can lead to significant issues, including damage to the unit and decreased heating capability.

How Does a Defrost Board Work?

The defrost board periodically checks the condition of the heat pump’s outdoor coils. It typically uses sensors to monitor the temperature and pressure of the coils to determine if frost build-up is occurring. When the sensors detect conditions that are conducive to frost formation, the defrost board initiates the defrost cycle.

During the defrost cycle, the heat pump temporarily reverses its operation, switching to cooling mode. This reversal causes the outdoor unit’s coils to heat up, melting any accumulated frost or ice. To ensure that the indoor environment remains comfortable during this process, supplemental heating systems are often activated.

Once the defrost board determines that the coils are clear of frost and ice, it ends the defrost cycle, and the heat pump returns to its normal heating operation. The duration and frequency of the defrost cycle depend on various factors, including outdoor temperature, humidity, and the specific settings of the defrost board.

Importance of the Defrost Board

The defrost board in a heat pump HVAC system is not just a component; it’s a crucial element that significantly impacts the system’s efficiency, reliability, and overall performance, especially in cold weather conditions. Understanding its importance is key for homeowners and HVAC professionals alike, as it underscores the need for proper maintenance and timely troubleshooting of any issues that may arise.

Ensuring Efficient Operation

One of the primary roles of the defrost board is to maintain the efficiency of the heat pump. In cold climates, frost and ice can accumulate on the outdoor unit’s evaporator coils. This accumulation acts as an insulator, hindering the coil’s ability to absorb heat from the outside air. The defrost board prevents this by periodically initiating a defrost cycle, thus maintaining the heat pump’s efficiency in transferring heat.

Preventing System Damage

Without a functioning defrost board, a heat pump is at risk of sustaining damage due to ice buildup. As frost accumulates, it can restrict airflow and place additional strain on the fan and other components. Over time, this can lead to mechanical failures, increased wear and tear, and potentially costly repairs. The defrost board helps to avoid these issues by ensuring that frost does not accumulate to a damaging extent.

Enhancing Comfort

The comfort of the occupants is a top priority in any HVAC system. A malfunctioning defrost board can lead to inadequate heating performance, as the heat pump struggles to extract enough heat from the outside air. By properly managing the defrost cycle, the defrost board ensures that the heat pump can continue to provide consistent and effective heating, even in cold weather.

Energy Efficiency

A heat pump with a malfunctioning defrost board can consume more energy than necessary. When the coils are frosted over, the system must work harder to maintain the desired indoor temperature, leading to increased energy consumption. By keeping the defrost cycle in check, the defrost board plays a significant role in maintaining the energy efficiency of the system, which is beneficial both for the environment and for reducing energy costs.

System Longevity

Regular and proper functioning of the defrost board contributes to the overall longevity of the heat pump system. By preventing excessive ice buildup and ensuring efficient operation, the defrost board helps to minimize the stress on various components of the heat pump. This can lead to fewer breakdowns and a longer lifespan for the system, ultimately saving money on replacements and extensive repairs.

Common Defrost Board Issues and Solutions

In the world of HVAC maintenance, particularly with heat pump systems, addressing defrost board issues is a critical task. These defrost board issues can vary in complexity and impact, ranging from minor annoyances to major problems that can compromise the efficiency and functionality of the entire system. Understanding and effectively resolving these defrost board issues is essential for maintaining the longevity and performance of your HVAC system. Let’s delve into some of the most common defrost board issues and explore their solutions.

1. Defrost Board Issue: Failure to Initiate Defrost Cycle

One of the most prevalent defrost board issues is the failure of the board to initiate the defrost cycle. This can lead to the accumulation of ice on the outdoor unit, significantly reducing the system’s heating efficiency.

Solutions:

- Sensor Check: The first step in resolving this defrost board issue is to inspect the temperature and pressure sensors connected to the defrost board. Faulty sensors can prevent the board from detecting the need for a defrost cycle.

- Board Inspection: Examine the defrost board for any signs of physical damage or corrosion. Such damage can be a primary cause of this defrost board issue.

- Electrical Connections: Ensure that all electrical connections to the defrost board are secure and intact. Loose connections can contribute to this defrost board issue.

2. Defrost Board Issue: Frequent or Prolonged Defrost Cycles

Another common defrost board issue is when the defrost cycle occurs too frequently or lasts longer than necessary. This can lead to increased energy usage and potential wear and tear on the system.

Solutions:

- Timer Adjustment: To address this defrost board issue, adjust the defrost timer settings on the board. This may involve consulting the system’s manual to understand the optimal settings for your specific model.

- Sensor Accuracy: Incorrect sensor readings can trigger unnecessary defrost cycles. Ensure that all sensors are accurately calibrated to avoid this defrost board issue.

- System Calibration: Sometimes, recalibrating the entire system can resolve this defrost board issue, ensuring that all components are functioning harmoniously.

3. Defrost Board Issue: Inability to Terminate Defrost Cycle

A defrost board issue that can cause significant inconvenience is when the defrost cycle fails to terminate properly, leaving the system stuck in defrost mode.

Solutions:

- Termination Switch Inspection: Check the termination switch or sensor responsible for signaling the end of the defrost cycle. A malfunction here can be the root of this defrost board issue.

- Wiring Examination: Inspect the wiring connected to the defrost board, as damaged or loose wires can prevent the board from receiving the correct signals to end the defrost cycle, leading to this defrost board issue.

- Board Testing: In some cases, conducting a thorough test of the defrost board’s functionality can help identify the cause of this defrost board issue. This may require specialized equipment and expertise.

4. Defrost Board Issue: Unusual Noises During Defrost Cycle

Unusual noises during the defrost cycle can indicate a defrost board issue, often related to the mechanical components of the system.

Solutions:

- Mechanical Obstruction Check: Ensure there are no obstructions or debris around the fan or coils that might be causing noise, as this can be a simple fix for this defrost board issue.

- Relay Switch Inspection: The relay switches on the defrost board can sometimes produce noise if they are faulty or failing. Replacing these switches can resolve this defrost board issue.

- Vibration Dampening: In some cases, adding or replacing vibration-dampening materials can reduce noise, addressing this defrost board issue.

5. Defrost Board Issue: System Not Heating Properly Post-Defrost

A defrost board issue that affects the system’s heating performance after a defrost cycle can lead to discomfort and inefficiency.

Solutions:

- Refrigerant Level Verification: Checking and adjusting the refrigerant levels can sometimes resolve this defrost board issue, as improper levels can affect heating efficiency.

- Reversing Valve Check: Inspect the reversing valve, which is crucial for switching the system back to heating mode after defrosting. A malfunction here can lead to this defrost board issue.

- System Diagnostics: Running a full diagnostic on the system can help pinpoint any underlying issues contributing to this defrost board issue, allowing for more targeted repairs.

Preventative Maintenance and Professional Help

Preventative maintenance is a critical aspect of ensuring the longevity and efficiency of your HVAC system, particularly in addressing potential defrost board issues. Regular maintenance not only helps in identifying and resolving issues before they escalate but also ensures that your system operates at its optimal capacity. Additionally, seeking professional help when necessary can save you time and money in the long run, while ensuring that your system is handled by experienced technicians.

Importance of Preventative Maintenance

Preventative maintenance involves regular check-ups and servicing of your HVAC system to keep it running smoothly. This proactive approach is key to preventing defrost board issues and other related problems. Here are some reasons why preventative maintenance is essential:

- Early Detection of Issues: Regular maintenance helps in the early detection of potential defrost board issues or other HVAC problems, allowing for timely repairs before they worsen.

- System Efficiency: Maintenance ensures that all components of your HVAC system, including the defrost board, are functioning efficiently, which can lead to energy savings and reduced utility bills.

- Prolonged System Life: By addressing minor issues promptly and keeping the system well-maintained, you can extend the lifespan of your HVAC system, avoiding premature replacements.

- Improved Air Quality: Regular maintenance includes cleaning and replacing filters, which can improve the indoor air quality of your home or business.

Key Preventative Maintenance Steps

To effectively prevent defrost board issues and maintain your HVAC system, consider the following maintenance steps:

- Regular Inspections: Schedule annual or bi-annual inspections with a qualified HVAC technician. These inspections should include a thorough check of the defrost board, sensors, coils, and other critical components.

- Clean and Replace Filters: Regularly clean or replace air filters to ensure proper airflow and system efficiency.

- Check Refrigerant Levels: Ensure that the refrigerant levels are adequate, as low levels can lead to system inefficiency and contribute to defrost board issues.

- Clean Coils and Fans: Keep the evaporator and condenser coils clean, as well as the fans, to prevent airflow restrictions and overheating.

- Inspect Electrical Connections: Check all electrical connections for signs of wear, corrosion, or damage, as these can lead to defrost board issues and other electrical problems in the system.

Seeking Professional Help

While basic maintenance can often be performed by homeowners, certain aspects of HVAC maintenance and repair should be left to professionals. Here are scenarios where seeking professional help is advisable:

- Complex Repairs: If you encounter complex defrost board issues or other intricate system problems, it’s best to hire a professional technician who has the expertise and tools to safely and effectively resolve the issue.

- Regular Inspections: Professional technicians can conduct in-depth inspections and identify issues that may not be apparent to the untrained eye.

- Safety Concerns: Working with electrical components and refrigerants can be dangerous. Professionals are trained to handle these elements safely.

- Warranty Preservation: Some repairs and maintenance tasks may require professional servicing to preserve the warranty of your HVAC system.

Preventative maintenance is crucial in avoiding defrost board issues and ensuring the optimal performance of your HVAC system. Regular check-ups, cleaning, and timely repairs can significantly extend the life of your system and improve its efficiency. When faced with complex issues or routine inspections, seeking professional help is a wise decision to ensure that your system is serviced correctly and safely. By combining preventative maintenance with professional expertise, you can enjoy a comfortable and efficient indoor environment year-round.

5 Common Defrost Board Issues and The AC Therapist’s Expert Solutions

In wrapping up this comprehensive exploration of common defrost board issues, it’s clear that these challenges, while potentially daunting, are surmountable with the right expertise and approach. Understanding the intricacies of defrost board problems – from failure to initiate the defrost cycle, to prolonged defrost periods, to issues affecting system performance post-defrost – is crucial in maintaining an efficient and reliable HVAC system.

At The AC Therapist, we pride ourselves on our deep understanding and expertise in handling these defrost board issues. Our commitment to providing the Tampa Bay area with top-tier HVAC services is unwavering. We recognize that each defrost board issue is unique and requires a tailored approach. Our team of skilled professionals is equipped with advanced tools and extensive knowledge, ensuring that every HVAC challenge is met with precision and efficiency.

Our services extend beyond just fixing immediate problems. We are dedicated to offering comprehensive solutions and preventative maintenance to safeguard your HVAC system against future issues. Our Therapy Maintenance Plans – available in Value, Premium, and Elite options – are designed to provide regular, thorough maintenance visits, coupled with additional perks such as exclusive discounts and inclusive services like duct sanitation, UV light installation, and more. These plans are strategically crafted to keep your HVAC system in pristine condition, thereby preventing defrost board issues and other potential complications.

Regular maintenance is the cornerstone of a healthy HVAC system. It not only prevents unexpected breakdowns and costly repairs but also ensures that your system operates at peak efficiency, ultimately saving you money and enhancing your comfort. By entrusting your HVAC needs to The AC Therapist, you’re choosing a partner deeply committed to the longevity and effectiveness of your heating and cooling solutions. Our team is ready to tackle any HVAC challenge with professionalism, dedication, and a customer-first mindset.

For all your HVAC concerns, especially those about defrost board issues, The AC Therapist is just a call away. We’re here to provide you with expert solutions, peace of mind, and a comfortable environment for your home or business. Let us take the worry out of your HVAC maintenance and repairs, ensuring that you can enjoy a comfortable and efficient space throughout the year.

In conclusion, when it comes to defrosting board issues and overall HVAC system care, The AC Therapist is your go-to expert in the Tampa Bay area. Our comprehensive services, tailored maintenance plans, and commitment to customer satisfaction position us as a leader in HVAC solutions. Reach out to us for any HVAC needs, and experience the difference that professional care and expertise can make in maintaining a comfortable and efficient environment.