What does the Reversing Valve do?

When it comes to heating, ventilation, and air conditioning (HVAC) systems, many components work together to keep our homes and offices comfortable.

One essential component that often goes unnoticed is the reversing valve. This valve plays a crucial role in the proper functioning of HVAC systems, particularly in heat pumps.

But what exactly does a reversing valve do, and why is it so important?

In this blog, we will explore the reversing valve‘s purpose, how it operates, and why it’s essential for the efficiency of your HVAC system.

What is a Reversing Valve?

A reversing valve is a device within a heat pump system that directs the flow of refrigerant.

It allows the heat pump to switch between heating and cooling modes, ensuring that your home or office remains comfortable throughout the year.

In essence, the reversing valve serves as the “switch” that enables your heat pump to alternate between providing warm or cool air.

The Importance of Reversing Valves

Heat pumps have become increasingly popular due to their energy efficiency and versatility. Unlike traditional HVAC systems, heat pumps can both heat and cool a space, making them a more environmentally friendly option. A key component of this versatility is the reversing valve, which allows the system to transfer heat in either direction.

Reversing valves are essential for the following reasons:

- Dual functionality: As previously mentioned, the reversing valve enables heat pumps to provide both heating and cooling. This dual functionality makes heat pumps a more cost-effective and space-saving option compared to installing separate heating and cooling systems.

- Energy efficiency: Heat pumps are generally more energy-efficient than traditional HVAC systems. The reversing valve contributes to this efficiency by allowing the heat pump to operate in the most suitable mode for the current conditions, reducing energy consumption and lowering utility bills.

- Improved comfort: By enabling the heat pump to switch between heating and cooling modes, the reversing valve helps maintain consistent indoor temperatures. This provides a more comfortable living or working environment.

How Does a Reversing Valve Work?

To understand the reversing valve’s function, it’s essential to know how a heat pump operates. A heat pump works by transferring heat between the indoor and outdoor environments. In heating mode, the heat pump extracts heat from the outdoor air and transfers it indoors, while in cooling mode, it removes heat from the indoor air and releases it outdoors. The reversing valve plays a critical role in this process by directing the flow of refrigerant, which is the substance responsible for heat transfer.

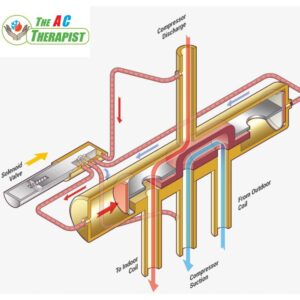

The main components of a reversing valve include:

- Valve body: The valve body houses the internal components and provides connections for the refrigerant lines.

- Slide: The slide moves within the valve body to direct the flow of refrigerant between the different ports.

- Solenoid: The solenoid is an electromechanical device that controls the slide’s position. When energized, the solenoid moves the slide to change the flow of refrigerant.

- Ports: There are four ports on a reversing valve, connected to various components of the heat pump system. These ports include the compressor, indoor coil, outdoor coil, and a common suction line.

The operation of a reversing valve can be broken down into two primary modes: heating and cooling.

- Heating mode: In heating mode, the solenoid is de-energized, and the slide directs refrigerant flow from the compressor to the outdoor coil. This causes the outdoor coil to act as an evaporator, absorbing heat from the outside air. The refrigerant then flows through the indoor coil, which functions as a condenser, releasing the absorbed heat into the indoor space.

- Cooling mode: When the solenoid is energized, the slide moves to redirect the refrigerant flow from the compressor to the indoor coil. In this configuration, the indoor coil acts as an evaporator, absorbing heat from the indoor air. The refrigerant then flows through the outdoor coil, which serves as a condenser, releasing the absorbed heat into the outdoor environment.

This is the mode for brands like Carrier, Goodman, Trane and others. On brands like Rheem, it is the reverse energized in the heater.

Common Issues with Reversing Valves

While reversing valves are generally reliable, they can encounter issues that may affect the performance of your heat pump system. Some common problems include:

- Stuck slide: Over time, debris, dirt, or sludge can accumulate within the valve body, causing the slide to become stuck. This can prevent the heat pump from switching between heating and cooling modes. Regular maintenance and cleaning can help prevent this issue.

- Solenoid failure: The solenoid is an electrical component that can fail due to various reasons, such as a damaged coil, burnt wiring, or mechanical issues. A failed solenoid can prevent the reversing valve from operating correctly and may require replacement.

- Leaks: Refrigerant leaks can occur at the connections between the reversing valve and the refrigerant lines. This can lead to reduced system efficiency and may require professional repair.

- Improper installation: If a reversing valve is installed incorrectly or connected to the wrong ports, it can cause issues with the heat pump’s operation. It’s essential to ensure proper installation and follow the manufacturer’s guidelines.

Troubleshooting and Maintaining Your Reversing Valve

Regular maintenance and inspection of your heat pump system can help extend the life of the reversing valve and prevent potential issues. Some maintenance tips include:

- Keep your system clean: Ensure that the outdoor unit is free of debris, dirt, and vegetation. This can help prevent the buildup of contaminants within the reversing valve.

- Schedule regular maintenance: Arrange for a professional HVAC technician to inspect and service your heat pump system periodically. This can help detect potential issues before they become severe and ensure that your system operates at peak efficiency.

- Check for leaks: Inspect the connections between the reversing valve and the refrigerant lines for any signs of refrigerant leaks. If you suspect a leak, contact a professional technician to address the issue.

- Monitor system performance: Pay attention to your heat pump’s performance and take note of any unusual noises or fluctuations in temperature. If you notice any issues, consult a professional HVAC technician for further assessment and repair.

What are the symptoms of a bad reversing valve?

A bad reversing valve can impact the performance of your heat pump system, leading to several noticeable symptoms. Some common signs of a faulty reversing valve include:

- Inability to switch modes: If your heat pump is unable to switch between heating and cooling modes or gets stuck in one mode, it may indicate an issue with the reversing valve.

- Reduced system efficiency: A malfunctioning reversing valve can lead to decreased energy efficiency, resulting in higher utility bills and poor temperature control.

- Inadequate heating or cooling: If your heat pump isn’t providing sufficient heating or cooling, even when set at the correct temperature, the reversing valve could be the culprit.

- Strange noises: Unusual noises, such as hissing or clicking, coming from the heat pump during mode changes may signal a problem with the reversing valve or its solenoid.

- Leaking refrigerant: Refrigerant leaks around the reversing valve connections can indicate a faulty valve or improper installation, impacting your heat pump’s performance.

- Frost or ice buildup: If you observe frost or ice forming on the outdoor coil while in heating mode, or on the indoor coil while in cooling mode, it could be a sign of a malfunctioning reversing valve.

If you experience any of these symptoms, it’s essential to consult with a professional HVAC technician to diagnose and address the issue. Ignoring a faulty reversing valve can lead to further damage to your heat pump system and compromise its performance and efficiency.

How much does it cost to replace reversing valve?

The cost of replacing a reversing valve can vary depending on several factors, such as the make and model of your heat pump system, the cost of the replacement part, labor fees, and your geographical location. On average, you can expect to pay anywhere between $600 and $1,200 for a reversing valve replacement, including both the parts and labor costs.

Keep in mind that the cost of the reversing valve itself typically ranges from $120 to $300, but the majority of the expense comes from the labor involved in the replacement process. Replacing a reversing valve is a complex task that requires the expertise of a professional HVAC technician, as it involves discharging and evacuating the refrigerant, removing the faulty valve, installing the new valve, and recharging the system with the appropriate refrigerant.

To get a more accurate estimate for your specific situation, it’s best to contact a local HVAC professional who can assess your heat pump system and provide you with a detailed quote. Remember that investing in regular maintenance can help prevent reversing valve issues and extend the life of your heat pump system, potentially saving you money in the long run.

How to Replace a Reversive Valve.

Replacing a reversing valve is a complex task that requires specialized knowledge, tools, and skills. It’s highly recommended to hire a professional HVAC technician to perform the replacement to ensure the safety and proper functioning of your heat pump system. However, if you are a trained professional or have experience with HVAC systems, you can follow these general steps to replace a reversing valve:

- Disconnect power: Always start by turning off the power supply to your heat pump system at the circuit breaker or disconnect switch to ensure safety.

- Recover refrigerant: Since the reversing valve is part of the refrigerant circuit, you’ll need to recover the refrigerant from the system using a refrigerant recovery machine. Connect the recovery machine to the system’s service ports and follow the manufacturer’s instructions for proper refrigerant recovery.

- Locate the reversing valve: In the outdoor unit (condenser), identify the reversing valve. It’s typically a cylindrical or tubular-shaped component with four refrigerant line connections and a solenoid attached to it.

- Remove the solenoid: Disconnect the wires from the solenoid and carefully remove it from the reversing valve. Set it aside if it’s still functional, or replace it if necessary.

- Disconnect the refrigerant lines: Using a tubing cutter, carefully cut the four refrigerant lines connected to the reversing valve. Leave enough tubing on the valve to allow for proper brazing when installing the new valve. If possible heat the connection to disconnect them without cutting.

- Remove the old reversing valve: Carefully remove the faulty reversing valve from the outdoor unit.

- Install the new reversing valve: Position the new reversing valve in the outdoor unit, ensuring the proper orientation. Align the refrigerant lines with the valve’s connections.

- Braze the connections: Using a brazing torch and brazing rods, carefully braze the refrigerant lines to the new reversing valve. It’s crucial to use a heat sink or wet cloth to protect the valve from excessive heat during the brazing process.

- Reinstall the solenoid: Attach the solenoid to the new reversing valve and connect the wires as per the manufacturer’s instructions.

- Perform a vacuum test: Connect a vacuum pump to the system’s service ports and perform a vacuum test to ensure there are no leaks in the system. The vacuum should be pulled down to 500 microns or lower and held for a minimum of 30 minutes to remove moisture and air from the system.

- Recharge the system with refrigerant: Using a refrigerant scale and manifold gauge set, recharge the system with the appropriate type and amount of refrigerant as specified by the manufacturer.

- Check for proper operation: Restore power to the heat pump system and test its operation in both heating and cooling modes. Check for any leaks around the reversing valve connections and ensure the system is functioning correctly.

Remember that replacing a reversing valve is a task best left to trained professionals due to the complexity and potential hazards involved. If you’re not confident in your abilities or lack the necessary tools and experience, it’s strongly advised to consult a professional HVAC technician to ensure the safety and efficiency of your heat pump system.

Where is the reversing valve located?

The reversing valve is located within the outdoor unit of your heat pump system, also known as the condenser unit. It is typically a cylindrical or tubular-shaped component with four refrigerant line connections. These connections link the reversing valve to various parts of the system, including the compressor, indoor coil (evaporator or condenser), outdoor coil (condenser or evaporator), and a common suction line.

The reversing valve can usually be identified by the presence of a solenoid coil attached to it. The solenoid is an electromechanical device responsible for controlling the movement of the slide within the valve, which directs the flow of refrigerant and allows the heat pump to switch between heating and cooling modes.

When working on or around the reversing valve, it’s essential to follow proper safety precautions and consult a professional HVAC technician if you’re unsure about any aspect of the process.

Unveiling the Reversing Valve’s Crucial Role in Heat Pump Efficiency and Comfort

In summary, the reversing valve serves as the unsung hero of heat pump systems, playing a pivotal role in their energy efficiency, versatility, and overall performance. By facilitating the switch between heating and cooling modes, the reversing valve ensures that your heat pump can cater to your comfort needs throughout the year, regardless of the season. Gaining an understanding of the reversing valve’s function, importance, and proper maintenance practices can help you make the most of your heat pump system and optimize its performance.

As a homeowner or building manager, it’s essential to have a trusted HVAC professional on your side to help maintain and repair your heat pump system when needed. The AC Therapist is your go-to partner for all your HVAC needs, specializing in heat pump systems and reversing valve maintenance. Our team of experienced and certified technicians is committed to providing you with the highest level of service, ensuring that your heat pump system operates at its peak potential.

By choosing The AC Therapist, you can expect:

- Expertise: Our team of skilled technicians has extensive experience with heat pump systems and reversing valves, allowing us to diagnose and resolve any issues effectively and efficiently.

- Comprehensive maintenance services: We offer a complete range of maintenance services, including regular system checkups, cleaning, and addressing any potential issues with your reversing valve or other heat pump components.

- Prompt repairs: If you encounter any problems with your heat pump system or reversing valve, our team is ready to respond quickly and provide the necessary repairs, minimizing any disruption to your comfort.

- Ongoing support: At the AC Therapist, we are dedicated to ensuring your long-term satisfaction. Our commitment to excellent customer service means that we will be there to support you with any future questions or concerns about your heat pump system.

Don’t wait for a reversing valve issue to compromise your heat pump’s performance or your comfort. Contact the AC Therapist today to schedule a comprehensive maintenance check and enjoy the peace of mind that comes from knowing your heat pump system is in expert hands. By partnering with us, you can ensure that your heat pump and reversing valve work together seamlessly, providing you with a comfortable, energy-efficient environment year-round.